- INFO@matltech.com

- E2-1-1011 Lub Chaw Haujlwm Thoob Ntiaj Teb, No.1700 Tianfu Avenue Sab Qaum Teb, Chengdu 610041, Suav

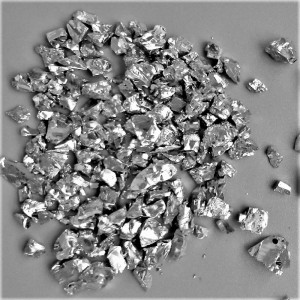

Tellurium Tooj Liab Alloy

Tellurium Tooj Liab Alloy, los ntawm kev maj mam ntxiv tsim cov qhov hnyav feem pua ntawm 99.99% ntshiab tellurium rau hauv molten coj mus muag ntshiab 9,99% tooj liab cathode hauv lub zog-zaus induction rauv taws, thiab tib lub sijhawm phosphorus ua rau lub deoxidant thiab microelements me ntsis xav tau ntxiv rau hauv cov kua roj kom tau txais qhov xav tau tellurium tooj liab alloy.

Ua superior dawb txiav kev ua tau zoo, uas ua kom muaj ntau dua qhov kev siv lub tshuab nrawm dua li qhov ua tau nrog cov ntshiab tooj liab, lub tshuab ua haujlwm nplai yog rated li 90, ob qho tib si ua haujlwm txias lossis kub tsim yog siv tau, thiab nrog zoo arc-resistance kev ua tau zoo, hydrogen embrittlement, siab dua hluav taws xob conductivity (90% IACS) thiab thermal conductivity, thiab tiv thaiv kev xeb, Tellurium Copper Alloy (C14500, CuTeP) feem ntau yog siv rau vuam (hydrogen txiav, acetylene txiav thiab argon-arc vuam cov cuab yeej), tshuaj lom neeg kev lag luam thiab cov tshuab ntxhia xws li lub tsheb carburetor nozzle, cov lus qhia vuam hluav taws xob, lub taub hau roj, cov roj teeb lub taub hau thiab lub tshuab hluav taws xob txuas, lub tshuab hluav taws xob ntawm lub tshuab hluav taws xob, cov hloov hluav taws xob & cov hluav taws xob txuas hluav taws xob, hloov lub zog thiab cov kev lag luam valve.

Txhua cov khoom lag luam ua raws RoHS cov kev cai.

Cov ntsiab lus

Cim npe

Kev Qhia Txog Kev Kawm

|

Tsis yog. |

Yam khoom |

Qauv Txuj Ci |

|||

|

1 |

Qib |

Te |

Rov |

P |

Cu |

|

2 |

Te-Cu |

0.2-0.35% |

0.03-0.05% |

- |

seem |

|

3 |

Te-P-Cu |

0.4-0.70% |

- |

0.004-0.012% |

seem |

|

4 |

Lub Zog |

H04, H02, O60 |

|||

| Lub zog Tensile |

265 Mpa Min |

||||

| Looj Ceeb |

8% Min |

||||

| Kev Siv Hluav Taws Xob |

90% IACS Min |

||||

| Cav Raug Qis Nqi |

90 Min [raws li HPb 63-3 (C36000)] |

||||

|

5 |

Qhov Coob | Nrum D90 hli × L (0.25-5) m, Extruded D (5-40) mm × L (0.25-5) m | |||

|

6 |

Txuj Ci |

ASTM-C14500 / GB-QTe0.5 / JIS-C1450 / DIN-CuTeP / BS-C109 |

|||

|

7 |

Ntim |

Hauv rooj plaub plywood |

|||

Cov Lus Qhia Yuav Khoom Siv

- Muaj Qauv Thaum Thov

- Kev Nyab Xeeb Kev Xa Cov Khoom Los Ntawm Courier / Huab Cua / Hiav Txwv

- COA / COC Tswj Xyuas Kom Zoo

- Kev Ruaj Ntseg & Cov Khoom Siv Yooj Yim

- UN Standard Packing Muaj Raws Li Thov

- Kev Tshuaj Ntsuam Xyuas Zoo suav nrog XRD / SEM / ICP / GDMS thiab lwm yam

- Daim Ntawv Qhia Txog Txhua Yam Kev Ua Lag Luam CPT / FOB / CFR / CIP Los Ntawm Incoterms 2010

- Saj zawg zog them nqe T / TD / PL / C Txais

- Kev Muag Khoom Zoo Tom Qab Kev Muag Khoom

- ISO9001: 2015 Muaj ntawv pov thawj & Rohs / REACH Cov Kev Pom Zoo

- Uas tsis yog-Tshaj Tawm Cov Lus Pom Zoo

- Cov Tsis Muaj-Cov Cai Cov Ntxhia Tso Cai

- Kev Tswj Xyuas Kev Tswj Xyuas Ib Leeg

- Ua Neej Raug Kev Txom Nyem

ntsig txog cov khoom lag luam

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu